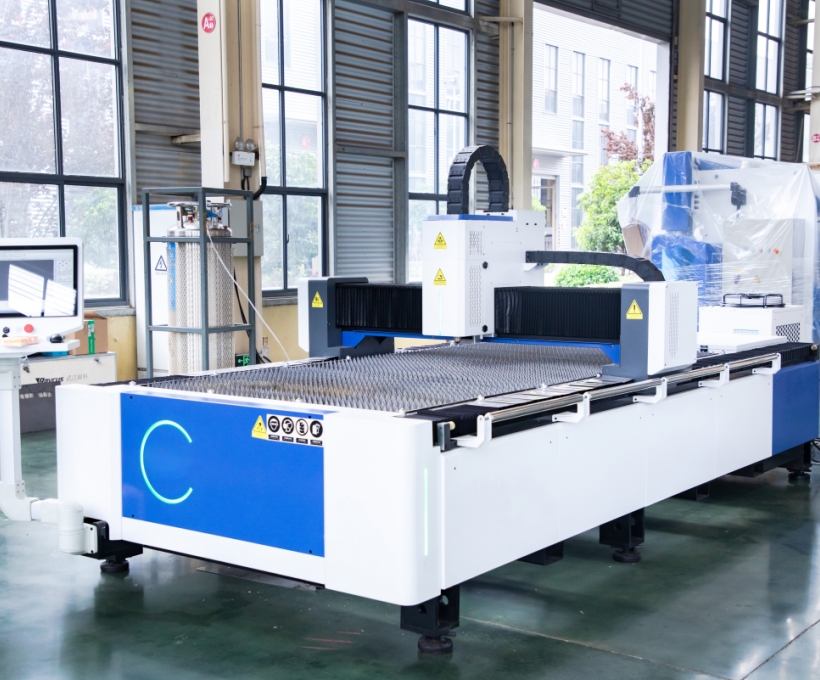

The metal fabrication industry has long been at the forefront of innovation, and the introduction of fiber laser cutting technology has been a pivotal moment in this journey. This advanced technology has not only transformed the way metals are cut and shaped but has also set new standards for precision, speed, and efficiency in metalworking. Let’s explore how fiber laser cutting is revolutionizing the metal fabrication process.

The Advantages of Fiber Laser Cutting

Fiber laser cutting offers a range of benefits that traditional metal cutting methods cannot match. The technology uses a concentrated laser beam to cut through metal sheets with extreme accuracy, resulting in cleaner, burr-free edges and minimal material waste. Here are some key advantages:

- Precision and Quality: Fiber lasers provide high-definition cutting with narrow kerf widths, which means less material is lost during the cutting process. This precision is essential for complex designs and tight tolerances.

- Speed: The speed at which fiber lasers cut through metal is significantly faster than traditional methods, such as plasma or waterjet cutting. This increased speed leads to reduced production times and higher output.

- Versatility: Fiber laser cutters can handle a variety of metal thicknesses and materials, including stainless steel, carbon steel, aluminum, and even titanium, making them a versatile tool for any fabrication shop.

- Cost-Effectiveness: Although the initial investment in fiber laser technology can be high, the long-term cost savings in terms of reduced material waste, lower energy consumption, and decreased maintenance requirements make it a cost-effective solution.

- Environmental Sustainability: Fiber laser cutting is a cleaner process that generates less heat and fewer fumes compared to traditional cutting methods, aligning with the growing emphasis on eco-friendly manufacturing practices.

Applications in Metal Fabrication

The versatility of fiber laser cutting technology has led to its widespread adoption across various industries:

- Automotive Industry: Fiber lasers are used to cut components for vehicles, from body panels to engine parts, with high precision and efficiency.

- Aerospace: In the aerospace sector, fiber lasers cut high-strength alloys and composites with the accuracy required for critical aircraft components.

- Heavy Machinery: For heavy machinery manufacturers, fiber lasers provide the strength and precision needed for large-scale metal fabrication.

- Architecture and Construction: In architectural applications, fiber lasers cut intricate metal designs for building facades, structural components, and decorative elements.

- Industrial Equipment: Manufacturers of industrial equipment rely on fiber lasers for cutting high-quality, precision parts that require minimal post-processing.

The Future of Metal Fabrication

As technology continues to advance, the capabilities of fiber laser cutting are expanding. Developments in laser power, beam delivery systems, and automation are pushing the boundaries of what is possible in metal fabrication. The future looks bright for fiber laser cutting, with the potential to further increase efficiency, reduce costs, and drive innovation in metalworking.

Conclusion

Fiber laser cutting technology has undoubtedly revolutionized metal fabrication, offering a cutting-edge solution that enhances precision, speed, and quality. As manufacturers increasingly adopt this technology, we can expect to see a continued transformation in the way metals are worked with, leading to more innovative and efficient products across all sectors. The future of metal fabrication is bright, and fiber laser cutting is at the heart of this exciting evolution.